Professional slip ring manufacturer

company profile

ABOUT US

Shenzhen JARCH Electromechanical Technology Co., Ltd. was established in 2006. It is a world-renowned R&D and manufacturer of the top ten professional conductive slip rings in China. It is one of the few professionals in the world that can integrate independent research and development, production, sales and warranty. One of the manufacturers of conductive slip rings.Shenzhen JARCH Electromechanical Technology Co., Ltd. is located in Songgang, Shenzhen. The factory covers an area of 3,000 square meters. It has an independent R&D team of dozens of people. It has specialized in the development of customized conductive slip rings for 15 years. + mature solutions for customers to choose at will, they use their skilled technology and rich knowledge to provide global customers with perfect solutions, so that the company can provide conductive slip rings for large domestic and foreign enterprises such as Huawei, Foxconn, BYD, Siemens, etc. for a long time. The customized service has laid a solid foundation.

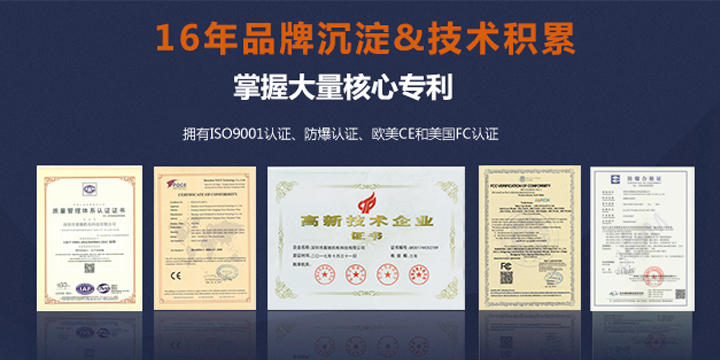

JARCH Electromechanical Technology has been rated as "National High-tech Enterprise" for many times since 2015, and has passed the "ISO9001" quality certification system for many years. All JARCH Electromechanical's conductive slip rings and rotary joints have obtained CE, FCC, etc. International certification, products are exported to more than 100 countries in the world, and have established long-term cooperation with more than 1,000 foreign companies, providing high-quality slip ring customization services for many foreign companies. At the same time, JARCH Electromechanical is one of the few domestic explosion-proof production licenses. One of the largest slip ring manufacturers, producing explosion-proof slip rings with professional explosion-proof certification.

With professional R&D technology, unique design concept, rich experience, high-quality quality, perfect after-sales, and 15 years of technical accumulation, JARCH Electromechanical Technology has successfully won the recognition of customers, and has become its various high-demand, high-end products. The preferred partner for precision conductive slip rings. The company's products are widely used by customers in a series of high-tech fields such as aerospace, marine diving, military equipment, wind power generation, automation equipment, etc., and solve various technical problems existing in the process of equipment rotation and transmission for the majority of customers.

After 15 years of continuous efforts, JARCH Electromechanical Technology has covered many series of waterproof slip rings, explosion-proof slip rings, optical fiber slip rings, HD slip rings, electric pneumatic slip rings, high temperature resistant slip rings, rotary joints, etc. Widely used in aerospace, marine diving, military equipment, wind power, industrial automation, oil and gas, medical food and many other high-tech fields. In the next few years, the company will continue to improve and innovate with its strong strength and technology. , become a leading brand in the professional manufacture of industrial conductive slip rings.

Strength description

It has specialized in R&D and production of conductive slip rings for 15 years. It has an independent R&D team with dozens of people and more than 10,000 mature solutions. It has long provided customized services for large domestic and foreign enterprises such as Huawei, Foxconn, BYD, and Siemens.

Brand Description

It has been rated as "National High-tech Enterprise" for many times, and has passed the "ISO9001" quality certification system for many years, and obtained CE, FC, FCC and other international certifications. Established long-term cooperation.

Case description

Products are widely used in aerospace, marine diving, military equipment, wind power, industrial automation, oil and gas, medical food and many other high-tech fields.

Quality Description

The internal contact material of the product is gold-plated, the shell is made of aviation aluminum alloy, the surface is anodized, and the rotating part adopts imported NSK bearings.

credentials

honor

research base

PHOTOS

Engineer team

photos