JSR-TH0735 Series Through Hole Slip Rings

Professional slip ring manufacturer

JSR-TH0735 Series Through Hole Slip Rings

Slip rings are devices that allow for the transmission of power and data signals from a stationary to a rotating object. They are commonly used in a variety of applications, including wind turbines, robotics, and military vehicles. While slip rings can be used for a variety of purposes, they are particularly well-suited for applications where space is limited or where high speeds are required.

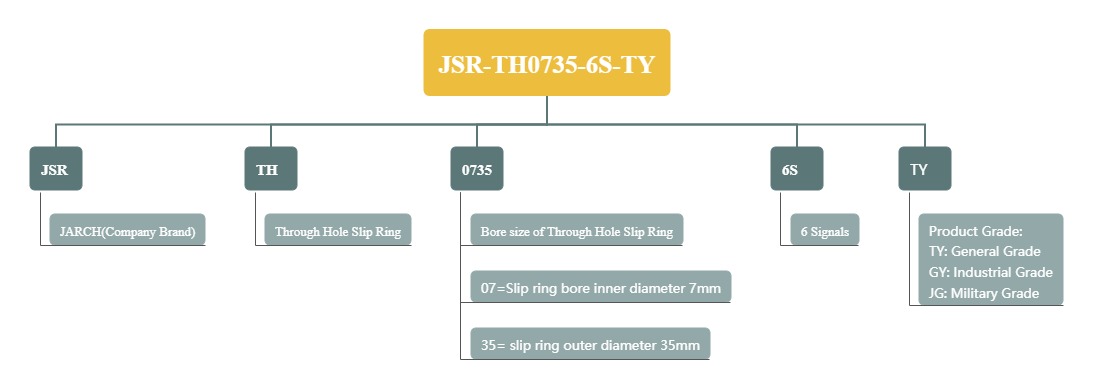

Model Ordering Instructions

型号定购说明

Product Grade Selection Table

SELECTION

Product Grade Gode | MAX. Speed | Working Life | Contact Material |

TY(General Grade | 250RPM | 20 million revolutions | Precious Metal |

GY(Industrial Grade) | 600RPM | 60 million revolutions | Gold plating - gold plating |

JG(Military Grade) | 1000RPM | 150 million revolutions | Golden alloy |

Technical Specifications

PARAMETER

Electrical Technical Parameters | |||||

Power | Signal | ||||

Spec. | Data | Spec. | Data | ||

Voltage range | 0-380VAC/VDC | Voltage range | 0-380VAC/VDC | ||

Insulation Resistance | ≥1000MΩ/500VDC | Insulation Resistance | ≥1000MΩ/500VDC | ||

Lead wire spec. | AWG16# Tinned Teflon | Lead wire spec. | AWG22# Tinned Teflon | ||

Rated current | Optional current for each channel | ||||

Electrical noise | 10mΩ@6VDC,50mA,5Rpm | ||||

Dynamic resistance change | <0.01Ω | ||||

Mechanical Data | |||||

Mechanical Performance | Environmental Performance | ||||

Spec. | Data | Spec. | Data | ||

Working Life | > 50 million revolutions (depends on working conditions) | Operating Temperature | -30C°-80C° | ||

Rated Speed | 300MRP(can be customized ) | Working Humidity | 0-85%RH | ||

Contact Material | Precious Metal (can be customized ) | Mechanical Vibration | MIL-SID-810E | ||

Shell Material | Aluminum Alloy (surface hard oxidation treatment) | IP Grade | IP51( IP65、IP68 Optional) | ||

Rotational Torque | 0.1N.M;+0.03N.M/ channel | ||||

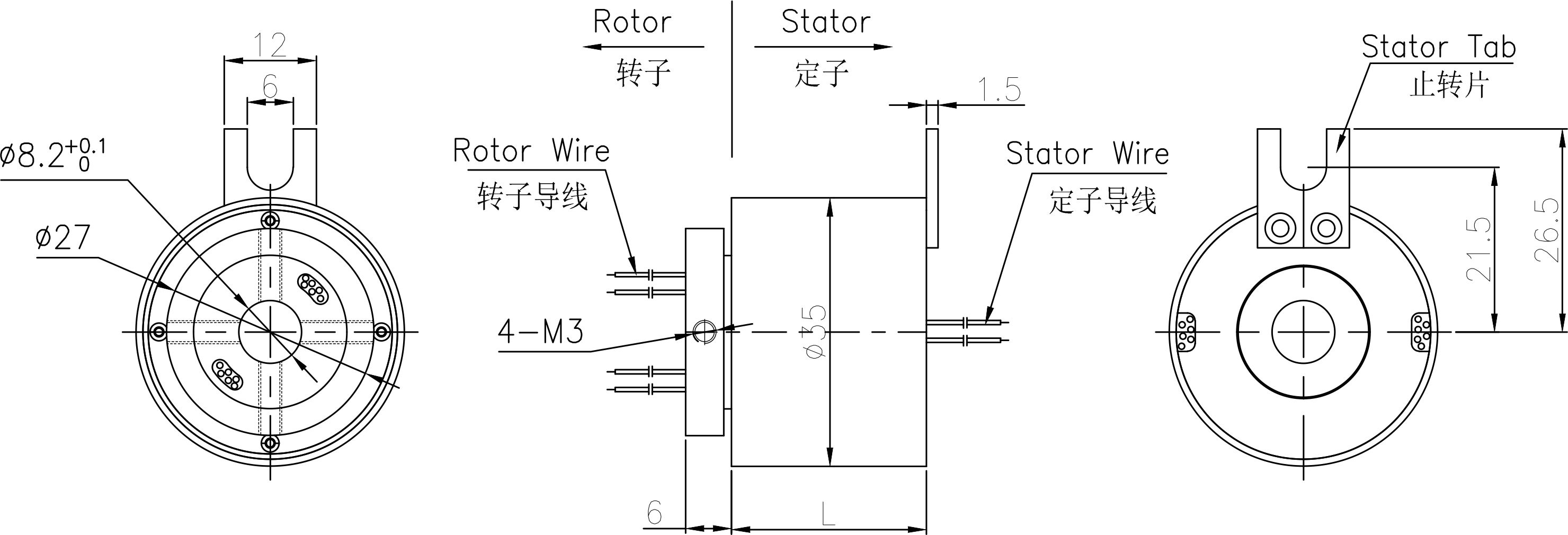

DRAWING

标准图纸

*If no standard models are suitable, contact us for custom solutions directly, thanks

Standard Products Selection Sheet

常规产品选型表

| TH0735-Series Through Hole Slip Rings Table | |||

| Model | Power Circuits (10A) | Signal Circuits(5A) | Length(L/MM) |

| JSR-TH0735-2S | 0 | 2 | 25.6 |

| JSR-TH0735-4S | 0 | 4 | 25.6 |

| JSR-TH0735-6S | 0 | 6 | 25.6 |

| JSR-TH0735-8S | 0 | 8 | 37.1 |

| JSR-TH0735-12S | 0 | 12 | 37.1 |

Color Code of Lead Wires

各环路导线色码表

| Ring No. | Color | Ring No. | Color |

| 1 | Black | 7 | Purple |

| 2 | Red | 8 | Grey |

| 3 | Yellow | 9 | Orange |

| 4 | Green | 10 | Brown |

| 5 | Blue | 11 | Transparent |

| 6 | White | 12 | Light Green |

| (Note: 12 colors are a group, with serial numbers 1...12, the next group repeats the first 12 colors, and each group is identified by a number tube as the group serial number.) | |||

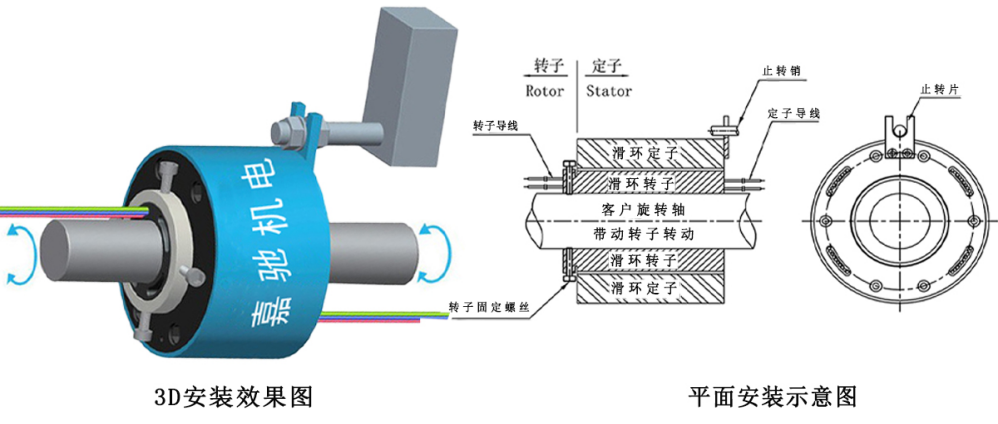

INSTALLATION

安装方式

OPTIONAL

Note: The following special requirements can be customized, the delivery time will increase by 3~15 days, and the cost will increase by 5%~50%. Most of the basic accessories of our company are standardized and modularized, and non-standard customization can also greatly reduce price and delivery.

The outgoing method and outgoing length of the rotor and stator can be customized.

Due to structural limitations, it can be customized according to the specified length or height, or outer diameter.

It can support up to 200 channels of power current or signal.

Optional aviation plug, terminal, and heat shrink tube.

Yaskawa, Panasonic, Siemens, and other servo system signal, power line, and encoder line hybrid slip ring.

Can mix high-speed data transmission (including Ethernet, USB, Profibus, ProfiNET, EtherCAT, CANopen, CANBUS, CC-LINK, RS232, RS485, and other industrial buses).

The temperature control signal and thermocouple signal are mixed.

Customized slip ring for special environments such as shockproof and high temperature.

It can be mixed with pneumatic and hydraulic rotary joints to form a gas-electric-hydraulic slip ring.

The low/high frequency and connector types can be customized.

The High-frequency power can be customized.

The number of channels can be customized according to requirements.

The maximum current can reach 5000 amperes (A).

Military level.

Waterproof, underwater mode optional, IP65, IP68 optional.

Requirements for stainless steel housing.

Applied Projects

适用项目

Drilling Platform

Drilling platforms are offshore structures primarily used for drilling wells. The platform is equipped with drilling, power, communication, navigation and other equipment, as well as safety life-saving and personnel living facilities, which is an indispensable means for offshore oil and gas exploration and development. The normal operation of the drilling platform is inseparable from the credit of the conductive slip ring. Many rotating parts on the drilling platform need to use the conductive slip ring. The conductive slip ring can smoothly and uninterruptedly transmit all parts of the drilling platform during the rotation process. The current and various signals are required to ensure the normal operation of each part of the drilling platform.

Blow Molding Machine

The bottle blowing machine refers to the machine that blows the bottle. The most simple explanation is the machine that can blow plastic particles (soften into liquid) or finished preforms into bottles through certain technological means. The bottle blowing machine is convenient and fast, and has a large amount of molding. After its appearance, it replaced most of the manual blowing machines and was adopted by most beverage companies. The more common models include a one-time molding hollow extrusion blow molding machine using PP and PE, an injection stretch blow molding machine using PET, PC or PP twice molding, and the newly developed multi-layer hollow extrusion blow molding and stretch blow molding machine. stretch blow molding.

Filling Machine

Filling machines are mainly a small category of products in packaging machines. From the perspective of packaging materials, they can be divided into liquid filling machines, paste filling machines, powder filling machines, and granule filling machines; from the degree of automation of production It is divided into semi-automatic filling machines and fully automatic filling production lines. In addition, in recent years, the level of science and technology has improved, and the domestic filling machine industry has also developed rapidly, with technical level, equipment performance, quality and other aspects. It has greatly improved and played an important role in supporting the efficient and safe production of enterprises.

Message consultation

Related products

product

correlation

news