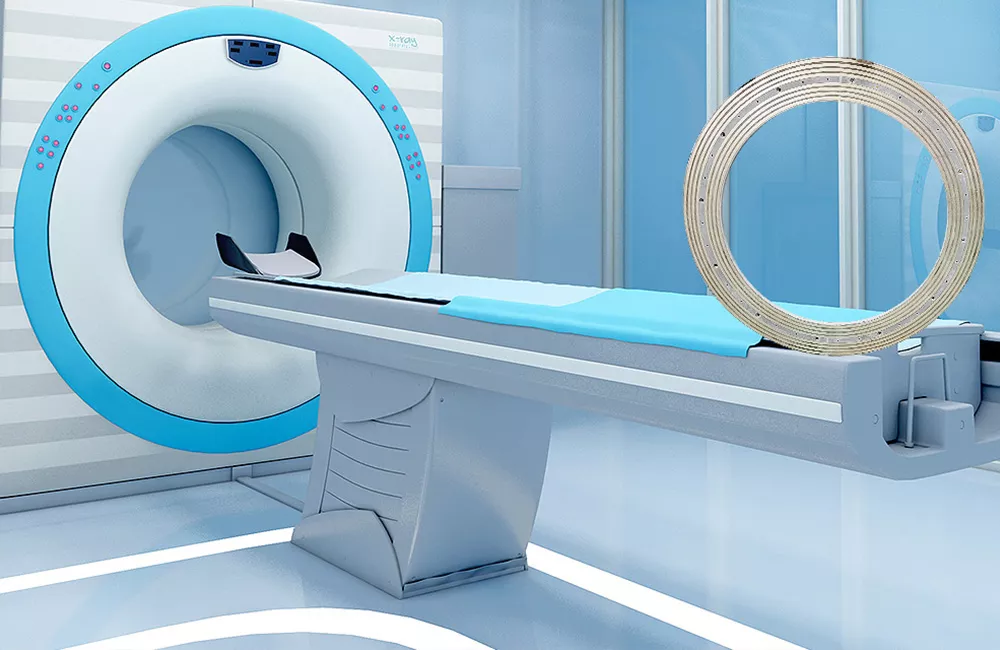

1. Check the appearance of conductive slip ring

Because the inside of the conductive slip ring cannot be seen, you can judge it from the outside. The appearance of slip rings produced by manufacturers with strict quality control requirements must be neat, tight in structure, smooth in design and processing, and no messy or damaged wires.

A manufacturer with strict control during production will generally not cut corners. This is to objectively evaluate the quality of conductive slip rings.

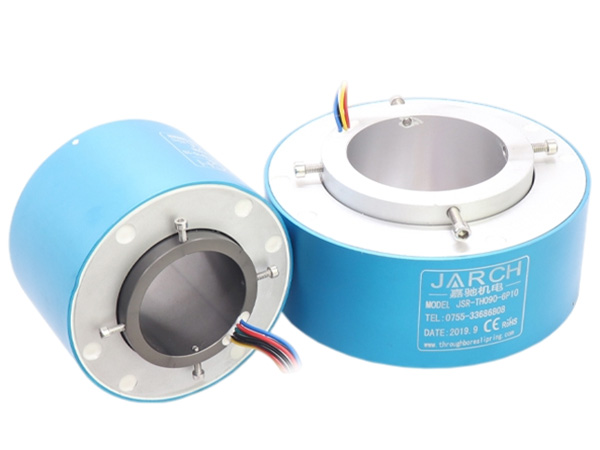

2. Check the material of the product shell

The use environment of the slip ring is very complex, and the material used for the shell is very important. Many unscrupulous merchants use cheap plastic as the shell, which will verify that the service life of the slip ring is affected, and there are serious potential safety hazards during the operation of the slip ring. Jiachi conductive slip ring is closely processed with high-strength aviation aluminum alloy. Its surface is treated with high-strength anodic oxidation. The material and superb technology can ensure that the slip ring can be used normally in various harsh environments.

3. Rotate to check the flexibility of the conductive slip ring

The conductive slip ring with good quality must have smooth hand feel, small torque, tight structure and no looseness and jamming when rotating. If you feel that the conductive slip ring you are rotating is in good condition, you can preliminarily identify it as qualified.

JARCH Electromechanical strictly controls the quality of conductive slip rings to ensure the quality of conductive slip rings and the safety of customers. If you want to test the quality of conductive slip ring in an all-round way, you need to use many professional testing equipment. Without professional testing instruments, Jiachi Electromechanical provides you with some simple and effective testing methods.

High speed slip rings have emerged in recent years according to the requirements of mechanical equipment. He requires that the rotating speed per minute exceed tens of thousands of revolutions, because the structure of the slip ring determines the high-speed contact and impedance. Therefore, high-speed slip rings are widely used. The development and production of high-speed slip rings in China has a history of nearly 5 years, and a large number of domestic slip rings have been equipped with automatic slip ring internal surface grinders in China. Most domestic high-grade high-speed machining center slip rings are imported products. The machining center slip rings developed and produced in China have been equipped with domestic machinery in small quantities.