****What are the customization and technical requirements for high-speed slip rings?

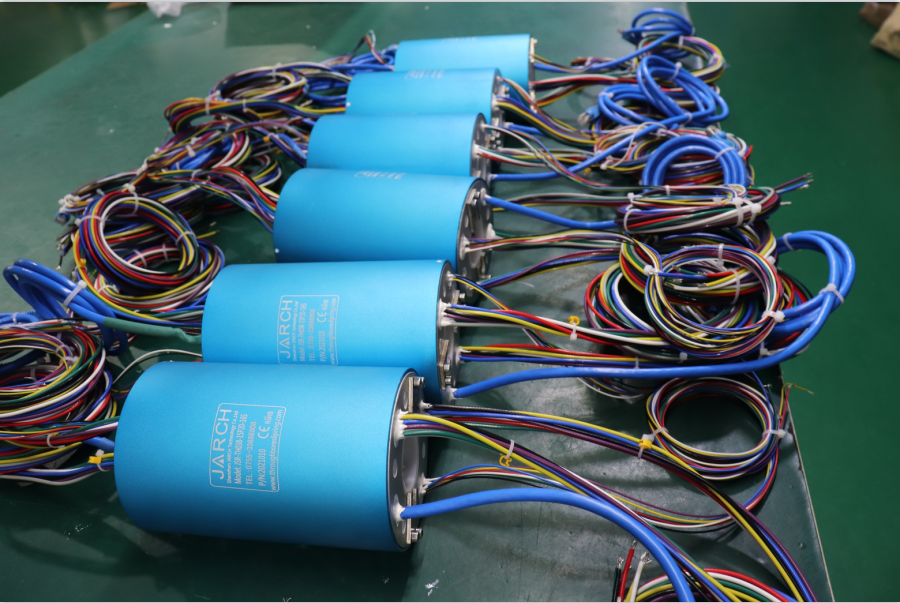

As a conductive slip ring, high-speed conductive slip ring is named for its resistance to high-speed operation. Generally, the speed of slip ring is below 600 RPM. For conductive rings with an outer diameter of more than 150 mm, the operating speed is generally between 0 and 300 RPM. Large size slip rings, etc. Exceeding this speed can be defined as high-speed slip ring. However, high-speed slip rings are also classified. JARCH high-speed slip rings are different from other slip ring manufacturers. Our high-speed slip rings are famous for their good quality and service life.

According to the requirements of mechanical equipment, high-speed slip rings have emerged in recent years. Because the structure of the slip ring determines the high speed of contact and impedance, it requires the speed to exceed tens of thousands of revolutions. Therefore, high-speed slip rings are widely used. The domestic development and production of high-speed slip rings have a history of nearly 5 years. The existing domestic automatic slip ring internal grinder is equipped with a large number of domestic slip rings. The slip rings of domestic high-end high-speed machining centers are mostly imported products. The slip rings of machining centers developed and produced in China have been equipped in small quantities by domestic machines.

Generally speaking, when purchasing conductive slip rings such as high-speed slip rings, many factors should be considered, as well as the material, working voltage, current, working speed, number of paths, and use environment of each component of the slip ring. To help users better understand high-speed slip rings, the following focuses on the selection of materials. Because there are many components of this type of slip ring, and the main components of the slip ring mainly affect the core performance of the product, we will explain in detail the selection of main materials of high-speed slip ring

****Do you know low frequency slip rings?

The conductive slip ring is a device that uses the sliding or rolling contact, electrostatic coupling or electromagnetic coupling of conductive parts to transmit electrical signals and energy to the rotating parts and static parts of the antenna base. Transmission elements, measuring elements and control elements on rotating parts must transmit control signals to the machine room and supply power to them. These all require different conductive slip ring devices to transmit signals and energy. Some radars need to connect as many as 100 lines. According to the frequency of the transmission signal, the slip ring assembly can be divided into: low-frequency slip ring, intermediate frequency slip ring and high-frequency rotary hinge. Generally, there are only the first two slip rings. Its electrical performance indicators are: insulation resistance, contact resistance, dielectric strength, crosstalk. For intermediate frequency slip ring, shielding, impedance matching, noise voltage, etc. should be considered due to high frequency. Its structural design should first ensure that the contact is reliable and that all lines are connected continuously. In this way, the brush materials are required to have good conductivity, appropriate pressure on the slip ring, small eccentricity and shaking of the slip ring, wear resistance, small friction torque and easy maintenance.

Low frequency slip ring is a slip ring device that uses sliding contact to transmit low frequency signal and energy. Common slip rings are divided into cylindrical slip rings and differential slip rings. Cylindrical slip rings can be divided into flat rings and V-rings. The conductive ring is generally made of more wear-resistant pure copper, coin silver and gold. The brush is composed of palladium, gold alloy or gold plated wire brush and copper graphite. If there are many slip rings, the cylindrical slip ring is composed of two sets of electric brushes and a set of differential rotary table (Fig. 1 Schematic Diagram of Differential Slip Ring), but its axial size is large. The use of differential slip rings can significantly reduce the axial size, volume and weight. The differential slip ring is composed of upper and lower sets of electric brushes and a set of differential adapter plate. The upper electric brush rotates with the antenna azimuth, and the lower electric brush is fixed. The differential adapter plate is provided with two groups of contact pieces, which are connected through the guide wire. The speed is 1/2 of the azimuth speed by using the differential mechanism. When the antenna rotates, the current flowing into each brush passes through one or two contact strip circuits and flows out from the corresponding upper brush to ensure that the circuit between the fixed part and the rotating part is always connected. Wear powder of slip contact slip ring will cause short circuit between rings. Therefore, it is necessary to ensure that the structure is easy to clean. Generally, the composite structure is used for on-site maintenance or replacement of components.

Intermediate frequency slip ring is a slip ring device used to transmit radar intermediate frequency (tens of megabytes) signals and energy. This slip ring has a high frequency and needs shielding. Common slip rings can also be used to transmit signals below 12MHz. A circular central conductor, the outer layer of which is a circular cable (Fig. 2 Intermediate frequency slip ring). The shielded slip ring of coaxial line type is usually used to transmit signals exceeding 12 MHz. This type of slip ring has a grooved section and is basically a rectangular coaxial conductor. In addition, the capacitance type intermediate frequency slip ring (Fig. 3) has a circular central conductor, which is supported in the shielding layer with an insulating pad. The rotating part and the fixed part maintain a gap without touching each other, and the intermediate frequency signal is coupled through capacitance. When the rotation range of the antenna is limited, a cable winding device can be used instead of a slip ring.