※ What are the common faults of slip rings?

The conductive slip ring is an indispensable small part of modern automation equipment. Modern conductive slip rings are widely used in various automation equipment. From the traditional carbon brush collector ring to the current brush slip ring of precious metal brush wire, the conductive slip ring has always existed to solve the rotary winding of equipment. The conductive slip ring has undergone a long and complex transformation from a single rotary conduction current to the mixed conduction of multiple media, However, many customers still don't understand what causes the conductive slip ring to fail easily. Today, the small editor of JARCH Electromechanical has sorted out the causes of common failures of conductive slip rings and shared them with you.

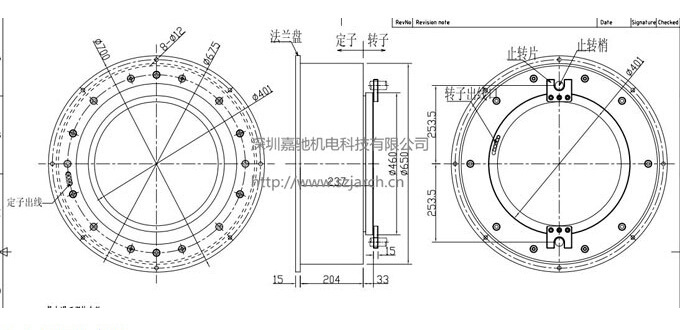

The conductive slip ring is divided into stator and rotor in the motor color plate. The conductive slip ring is used to connect the three-phase outgoing line of the winding with the external circuit through the brush. Its common faults include wearing on the working surfaces, insulation damage, loose coordination, excessive temperature, etc. The causes are analyzed as follows:

1. After the working surface of the collector ring is worn, there will be spots, brush marks, unevenness, corrosion, burns, cracks, ovalization, metal peeling, and other defects.

The reason is that there are hard particles in the brush or abrasives adhered between the brush and the carbon brush conductive ring working surface, or the quality of the collector ring is poor.

2. The operating temperature of the collector ring is too high.

The reason is that the collector ring has good contact with the brush, the contact area is too small (less than 70%), and the outgoing current density is too high; Too small or too large brush pressure will also cause poor contact between the collector ring and the brush, resulting in too high operating temperature of the collector ring.

3. The collector ring and plastic are loose.

For example, the plastic collector ring is made of 4330 phenolic fiber plastic and three copper rings. After the collector ring is used, the plastic shrinks deform, cracks, etc., causing the collector ring to loosen.

4. The collector ring insulation is damaged.

※ Fault analysis of the slip ring

In the small and medium-sized wound rotor, asynchronous brake motor, assembly collector ring, and conductive ring are generally used. In use, mechanical damage and thermal damage are caused by aging of the insulating sleeve, loose collector ring, local overheating caused by poor contact of outgoing line welding, damage of conductive rod insulating cylinder, brush box displacement, etc. There is also a plastic collecting ring. As the plastic becomes brittle and cracks occur, the carbon powder and oil dirt falling from the abrasion of the electric brush enter the cracks, or the carbon powder accumulates between the collecting rings, causing the breakdown between the collecting ring and the shaft to the ground and between the conductive rings.

※ how large can the size of the slip ring be?